How data-driven design increased user engagement by 26% and reduced onboarding time by 4x

Why was I hired

I was hired for in the product growth team to analyse the user behaviour

Outcome

We designed a mobile and web app tailored for Emiza’s entire supply chain workflow. The result? It prevented revenue leakages and 70% drop in customer support calls—driven by better adoption, visibility, and trust.

My Role

I led user research and UX design for the platform. While UI and development were handled by a partner agency, I guided the team during implementation.

Background

India’s supply chain is complex: patchy infrastructure, inconsistent SOPs, and deep resistance to digital tools.

Emiza was growing fast but couldn’t scale its operations due to manual workflows, lack of visibility, and limited software adoption by ground staff.

Their US-based off-the-shelf solution was failing to meet the needs of Indian warehouses.

I was brought in to help design a product from scratch—one that would bridge gaps across teams, simplify processes, and actually get used.

The Beginning

When I first joined the project, the ask seemed straightforward: design an in-house system to manage supply chain operations better than their current US-based software. But within the first few conversations, it was clear that the problem wasn’t just technical—it was cultural.

Operations teams were drowning in manual processes. Ground staff hesitated to adopt digital tools. And there was an unspoken fear that new systems would create more problems than they solved.

I realized that before we could design anything, we had to understand the day-to-day lives of the people who would actually use this system—and earn their trust.

Research Phase

We flew to Emiza’s Delhi warehouse and spent a full week on-site. The first couple of days were quiet. Staff were skeptical—unsure of who we were or why we were watching them work.

So we stopped acting like researchers, and started being present. We helped move boxes, joined water cooler conversations, and sat down for chai and jalebis during breaks. That small act of being human made a big difference. By mid-week, conversations started to flow. People began opening up—not just about the tasks they did, but the frustrations they felt.

We conducted contextual inquiries, shadowed multiple shifts, and ran informal interviews across six user groups:

Ground staff (GSPs)

Warehouse managers

Customer support teams

Billing & Finance

Central Ops

End customers (through secondary feedback)

Interviewing Billing and Management Team

Interviewing Business Analyst

GSP creating a Docket during Pickup

Marking consignment with codes

Gathering the insights

Back in Pune, we turned hours of observations, photos, and voice notes into patterns. Using affinity mapping, we clustered our findings by role, friction points, and behaviors.

What stood out was this: technology wasn’t the blocker—distrust was. Many employees had seen software come and go, with little benefit to their own workflow. Some even saw it as a threat to their job security or autonomy.

That insight reframed everything. Instead of focusing on "features," we started focusing on trust, clarity, and control.

These early insights informed the entire product strategy. We stopped asking, “What should this feature do?” and started asking, “What will help this person feel in control, not exposed?”

Redefining the Problem

How might we build a system that earns trust, reduces friction, and works the way people already think and operate?

That question guided every solution that followed.

Quick Sketch that I created to Illustrate need of Multiple Platforms

Building Trust with Ground Staff

What I found

GSPs and ops staff thought the system would replace them, expose their errors, or cut into income.

What I did:

Involved them in design validation to give them importance

Introduced guided flows to reduce mistakes, not punish them

Proposed gamified incentives—rewarding accuracy, not just speed

Impact

Adoption increased. They began taking ownership of the app instead of avoiding it.

Reducing Calls and Chaos Across Warehouses

What I found

Too many people were chasing information all day long—through calls, and spreadsheets.

What I did:

Created detailed end-to-end workflows for each user group

Mapped what information each role needed, and when

Designed a smart notification + dashboard system that pushed the right info to the right people

Impact

Less chasing. More doing. Support tickets dropped, and ops ran more smoothly.

Reducing Training Time for a High-Churn Ground Staff app

What I found

GSPs frequently changed. Training was inconsistent, and new staff made avoidable mistakes.

What I did:

Broke all tasks into small, guided steps with visual cues

Automated manual data entry wherever possible

Ensured offline access so work wouldn’t halt during poor network conditions

Impact

New GSPs became productive faster. Errors decreased. Managers had more confidence in new hires.

Preventing Malpractices Without Killing Morale

What I found

Some staff were using the system for personal shipments. Leadership needed control—but without creating fear.

What I did:

Introduced system checkpoints that ensured traceability

Designed a low-cost barcode seal system for locking truck door

Made delivery handoffs verifiable, even in remote warehouse

Impact

Revenue leakage dropped. Audit transparency improved. And users didn’t feel like they were under constant watch

Smarter Planning for operations staff

What I found

Warehouse managers used WhatsApp + whiteboards and tons of calls for daily shipment planning.

What I did:

Created a drag-and-drop Planning Board based on zones, vehicle type, ground staff and volume

Made it tablet and touch-friendly so they can work on the go

Allowed filtering and smart scheduling

Impact

Better dispatch planning, fewer missed pickups, and reduced stress for managers.

Giving Regional Managers Actionable Insights

What I found

Regional Managers were expected to oversee daily operations across multiple locations—but had no clear view of where delays were happening. Reports were delayed, cluttered, and reactive.

What I did:

Created a dashboard tailored to their role, surfacing relevant KPIs

Focused on trend-based data and exceptions—not just raw volume\

Designed the interface to support proactive planning

Impact

Regional heads could now act quickly on patterns, assign help where needed, and reduce micromanagement calls. Visibility led to stronger leadership at scale.

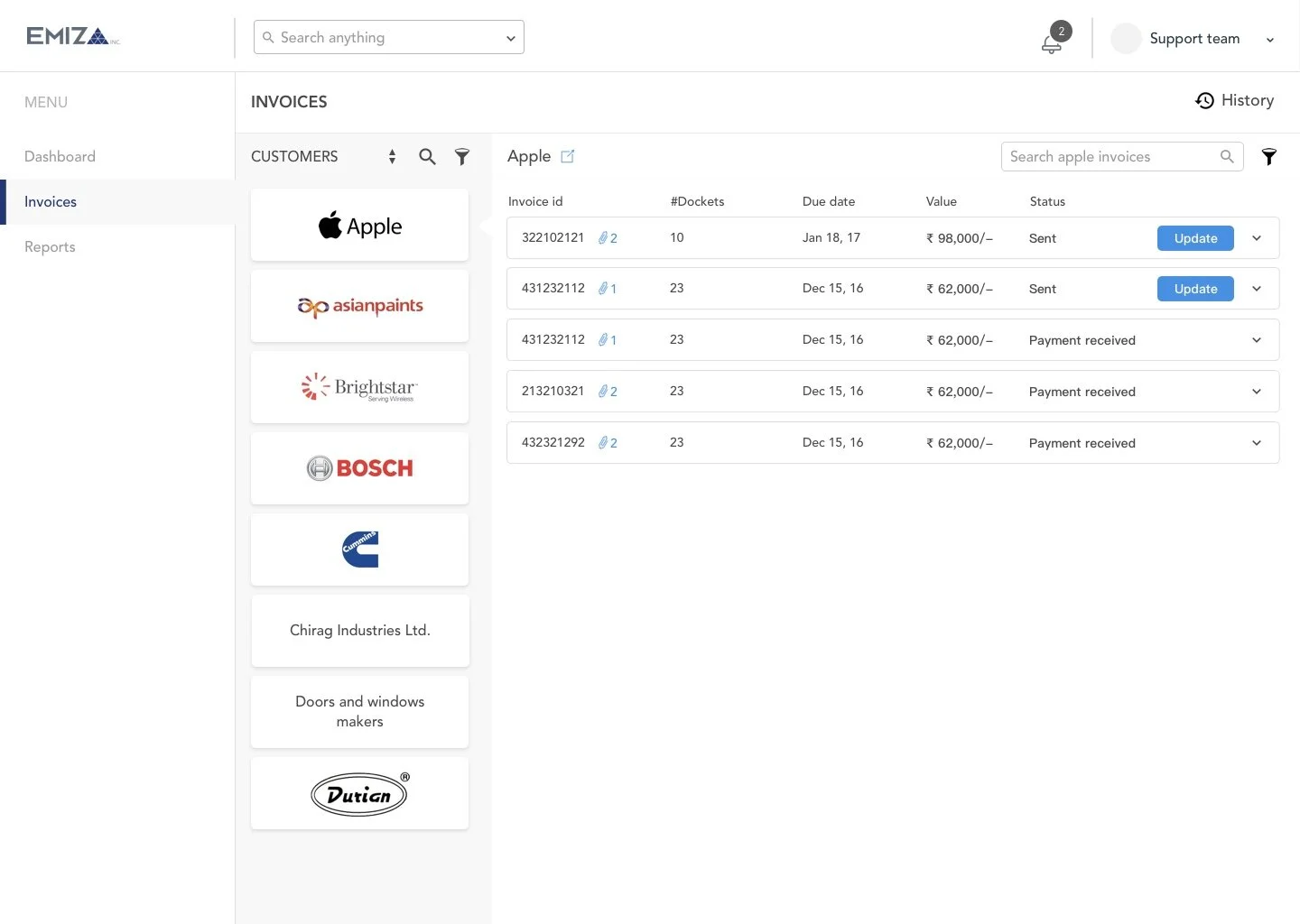

Streamlining Payment Management for Billing Teams

What I found

The billing process was confusing and disconnected from actual shipment flows. Teams were forced to rely on WhatsApp updates and manually tracked delivery slips.

What I did:

Linked pickup and delivery statuses directly to billing workflows

Made payment checkpoints actionable inside the system

Reduced dependency on manual proof-sharing and offline handover

Impact

The billing team could now raise invoices faster and with fewer errors. Fewer disputes. Less chasing. Better cash flow.

What I found

Support teams received daily calls from clients asking, “Where is my shipment?” Even internal teams lacked real-time visibility into package status.

What I did:

Designed an intuitive tracking system with clear status stages

Mapped real-world milestones to digital checkpoints (e.g. pickup confirmed, truck sealed, in transit, delivered)

Enabled proactive alerts to reduce the need for inbound calls

Impact

Support tickets dropped significantly. Customers gained clarity. And internal trust in the system went up.

Simplifying Consignment Tracking

Business Impact

📉 Revenue leakage and support calls reduced by over 70%

📲 Increased app usage and reduced training dependency

🤝 Smart suggestions reduced operations cost

📦 Real-time visibility and unified workflows across the org

It gave a competitive edge to Emiza. Emiza became Airtel's fulfillment partner for India and distributed the Apple Bestseller ‘iPhone X’

“Uday and his team spent sufficient time understanding all the Workflow, Pain Points, Uncertainties of the unorganized Supply Chain Industry. They shared valuable insights after a week of User Research.

He seamlessly connected all touchpoints across Cloud App, Mobile App, and Shipment tracking websites. His carefully crafted solution was Tailor-made for our Business and fulfilled our Business Objectives. I recommend him for any UX design work and look forward to working with him in the future.”

— Ajay Rao, CEO, Emiza

What I Learned

Always have backup plan ready in case something doesn’t work

Sometimes critical problems have simple solutions. Eg. Trackable Plastic Seals

Adoption isn’t about features. It’s about trust.

Jalebis help more than you’d expect. Working and sharing meals with ground staff workers was eye-opening experience.